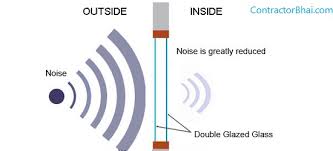

Soundproofing is important in a home for a myriad of reasons. First, you want to keep the noise out! When you close your windows you expect them to soundproof your home. Is your neighbor’s kid learning the trumpet? Need glass soundproof windows and! Traffic noise getting to be too loud? Then you need your glass windows to be soundproofed

What type of glass is best for soundproofing? The thicker the better!

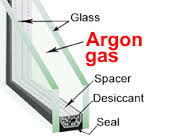

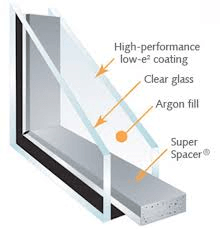

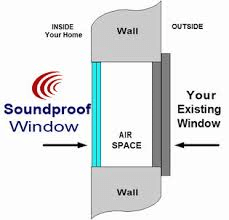

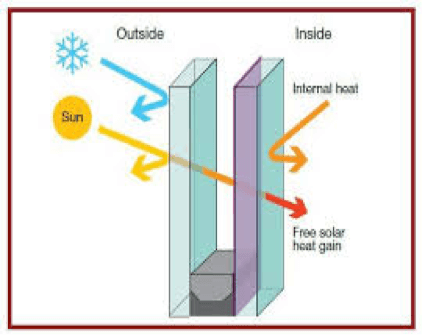

Double-glazed soundproof windows are best for soundproofing your home. A double-glazed window pane is a much better soundproof tool than a single-paned glass window. With the correct glass types, these units can help soundproof your home by reducing the noise in your house by up to 25%!

Our lives are continually disrupted by noises from neighbours, traffic, railways, industrial facilities, loudspeakers, pubs, and aircraft, which prevents us from finding the peace we so desperately need.

Windows and doors are usually the weakest point of sound insulation in the home and the problem gets worse with traditional windows or doors which have gaps even when closed. The gaps – a result of flaws in the design, construction, or installation – allow easy passage for noise to just barge in and destroy the tranquillity of a home.

Not so with Economy Glass soundproof windows and doors, which when closed block out the outside disturbances, creating a comfortable environment to concentrate, enable a peaceful night’s sleep, relax and enhance your quality of life. Below are the features that help Economy Glass protect you from your city:

Some common tips for reducing noise through your windows

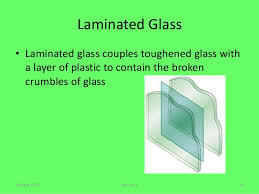

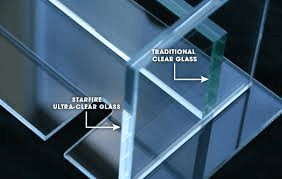

Consider laminated glass within the double-glazed units. Laminated glass has a plastic interlayer that helps eliminate a wide frequency of sound waves.

Consider specialty laminates (sound stop) These products have been specifically designed for reducing noise and with the correct installation method, sealants, and adhesives you will hear a clear reduction in unwanted noise.

Consider using two different glass thicknesses when installing double-glazed units. This is scientifically proven to eliminate a wider range of sound waves.

Before spending any money on soundproofing by buying new soundproof windows then you can try a few do-it-yourself tricks.

Check gaps in the soundproof windows frame and patch them to reduce noise instantly.

Fabric curtains are a great soundproofing tool although they only work when pulled.

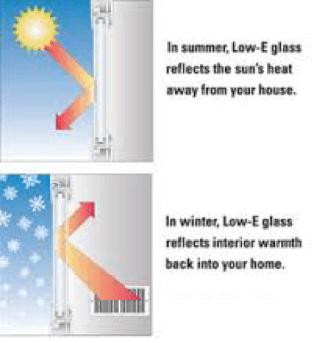

Insulation – ensure your home is adequately insulated within walls, floors, and ceilings

Plants also absorb sound so next time you are out pick up a pretty potted plant!

Contact us today for soundproof windows and soundproof doors