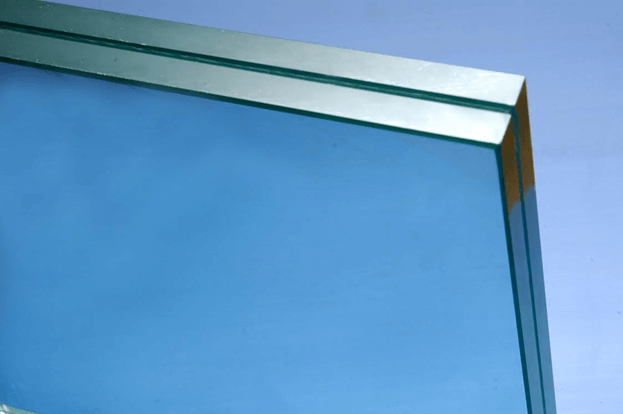

Image courtesy of Shutterstock

Beyond the safety features, laminated glass is also utilized to enhance a window’s sound insulation rating and block most ultraviolet radiation.

Laminated glass has a long history of applications. Despite it, many are concerned about its issues with de-lamination, a reduction in the adhesive that bonds the glass panes and the inter-layer together.

Where Does It Occur?

De-lamination, otherwise known as edge or inter-layer staining, is a phenomenon that typically occurs around fixing or at the edge of the glass pane. This staining usually most pervasive in safety glass panes where an inter-layer called Poly-vinyl Butyral (PVB) is used.

What Causes Laminated Safety Glass to De-laminate?

1. Excessive moisture

De-lamination is most prevalent during humid weather. That’s because PVB absorbs moisture. Thus, when the panes constantly exposed to warm and moist environments, the adhesive between the film and the glass loses its bond and the glass begins to de-laminate over time.

To prevent excessive moisture buildup, allow the edge of the inter-layer to breathe. During installation, make sure that the edges well-ventilated so that moisture won’t trickle down to the inter-layer and the adhesive.

2. Compatibility Issues

Often, the problem lies in the structural silicone or gasket that was use to bond the panes and inter-layer. If it is not compatible with the interlayer of the laminated glass, de-lamination could occur more rapidly.

If you’re in the market looking for laminated glass, consider manufacturers who offer information pertaining to product compatibility to ensure that the interlayer and the gaskets used in the glass are compatible.

3. Mismatched Glass Plies

Like toughened glass, heat-strengthened laminated glass usually exhibits barely visible distortions or waves, which caused by the rollers during manufacturing. When the glass plies do not have a matching distortion, trough to trough and peak to peak. It places stress on the interlayer of the laminated glass, which could lead to de-lamination.

In this light, manufacturers must have a stricter quality control procedure to prevent mismatched plies.

4. Poor Installation

As mentioned, the installation plays a critical role in moisture build-up between the panes. Without ventilation during the installation process, moisture could accumulate and cause the laminated glass to de-laminate.

Apart from that, the residue from the primers and cleaners that we use to prepare the glass prior to bonding with its structural silicone could deteriorate the adhesives, thereby contributing to de-lamination.

To ensure that contaminants do not come in direct contact with the inter-layer, the inter-layer of the laminated glass is not compressed by the fitting or the frame as this may cause voids, whereas contaminants can accumulate.