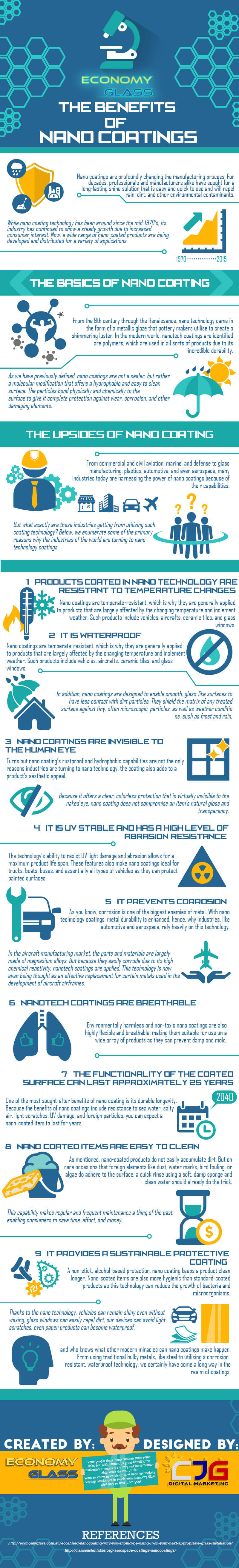

Nanocoatings are profoundly the manufacturing process. For decades, professionals and manufacturers alike have sought a long-lasting shine solution that is easy. And quick to use and will repel rain, dirt, and other environmental contaminants.

While nanocoatings technology has been around since the mid-1970s. It’s the industry has continued to show steady growth due to increased consumer interest. Now, a wide range of nano-coated products are being developed and distributed for a variety of applications.

From the 9th century through the Renaissance, nanocoatings technology came in the form of a metallic glaze. That pottery makers utilize to create a shimmering luster. In the modern world, nanotech coatings identified are polymers. Which used in all sorts of products due to their incredible durability.

As we have previously defined, nanocoatings are not a sealer, but a rather molecular modification that offers a hydrophobic and easy-to-clean surface. The particles bond physically and chemically to the surface to give it complete protection against wear, corrosion, and other damaging elements.

From commercial and civil aviation, marine, and defense to glass manufacturing, plastics, automotive, and even aerospace, many industries today are harnessing the power of nanocoatings because of their capabilities.

But what exactly are these industries getting from utilizing such coating technology? Below, we enumerate some of the primary reasons why the industries of the world are turning to nanocoating technology.